Magnetic Flow Meters

Product Support and Customer Service

For Further support visit our Contact Page

Overview

A majority of Ultrafiltration (UF) customer complaints can be traced to low paint flow. Low paint flow leads to the formation of a gel layer on the surface of the UF membrane, which restricts the passing of permeate through the membrane. An economic solution to maintaining proper paint flow is to install a magnetic paint flow meter at the inlet of the ultrafilter. If the flow meter saves one change of UF elements, it will pay for itself.

How can low paint flow happen?

Remember, in a perfect world, permeate rate is a function flow through the UF element, pressure drop across the element and temperature of the paint. With a centrifugal pump, pressure and flow are independent of each other. When adjusting the inlet and outlet valves to set a 30 psi pressure drop across the element, paint flow can easily change depending on the pump’s performance curve, pump condition, condition of prefilter bags, blocked pump suction etc.

Look at the paint pump discharge pressure gauge.

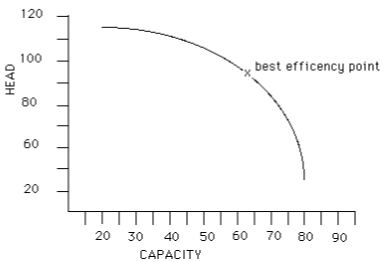

Another method was to look at the pressure gage on the pump discharge (this gauge must be located BEFORE the very first valve, or this method will not work). With the ‘pump outlet’ pressure you can find the corresponding flow rate on the pump’s curve (a sample is shown below).

A typical pump curve will show that as the flow rate (capacity or flow as shown on the horizontal axis) is increased the head (pressure, shown on the vertical axis) is reduced. Ideally you would like a pump curve as shown above so you can estimate the flow rate within +/- 75 lpm (20 gpm), or so. However in many cases the pump curve is actually very flat (almost horizontal). The implication is then that for a narrow range of pressure you can have a range of maybe a thousand lpm (hundred gallons of flow). With this pump curve it is impractical to use the pump discharge pressure and the pump.

How does the magnetic paint flow meter work?

It relies upon a Hall effect sensor that picks up variations in a changing magnetic field. This means that the fluid being measured must be at least ~25 micoSiemens/cm in conductivity, which is always the case. The faster the flow the more variation there is in the magnetic field. Magnetic meters have no moving parts and propeller type flow meters can not tolerate the level of solids that are typically in the E-coat paint bath.

How else is paint flow measured?

The other two types of ‘non-contact’ paint flow measurement is a Doppler radar type and a transit time or ultrasonic type. These are portable meters and work in many cases, with the transit time a better method. However these are portable meters and must be installed each time (with the use either a sugar based or silicone based lubricant between the sensor and the pipe carrying the fluid to measured. UFS recommends the TigerMag EP by Sparling Instruments, which more information can be accessed at Sparling Instruments

It is available in the flowing sizes: 2”, 3”, 4”, 6”, 8”, 10”, and 12”. The typical liner material is Tefzel®, which is suitable for most E-coat paints. If you plan to use PVC piping, the grounding rings on either side of the TigerMag EP are required. The normal input voltage is 77 to 240 VAC 50/60 hz and there is an option for 24 VDC input power. The standard output is a 4-20 mA [Note - the full scale flow rate, typically what the pump is capable of at the design output pressure is required at the time of ordering so the proper adjustment for the 4-20 mA output can be made.] The smaller sizes start at about $2650 and the larger ones can be several times more. This may sound like a lot of expense, but when you consider the cost of a single UF Element and if its life is shortened and has to be replaced, it does not take too many to pay for the TigerMag in the first place. UFS also recommends the use of transient surge protection on the incoming AC power and this included when you purchase the meter from UFS. The piping installation of the TigerMag iEP is a lot easier than most portable ultrasonic or transit time flow meters as only 3 x pipe diameters of straight pipe is required on either side. With the TigerMag EP paint flow meter the typical control points for the UF machine are to look at the paint flow and also take a look at the paint outlet manifold pressure (this should be ~1 bar [10 –15 psi]) and that is all.

BULLETIN 991404