TruPoint Quick Start

Contents

- 1 Product Support and Customer Service

- 2 Unboxing

- 3 General

- 4 Check Battery Condition/Wake Logger Up

- 5 Charge Battery

- 6 Getting ready to Run

- 7 Making the Data Run

- 8 After the Run

- 9 Low Battery

- 10 Full Battery

- 11 Ready To Arm

- 12 Armed

- 13 Logging

- 14 Viewing the Data

- 15 After the Run

- 16 Factory Default Set-up Parameters

- 17 How to Perform 9V Battery Test

Product Support and Customer Service

For Further support visit our Contact Page

Unboxing

General

The TruPoint Logger is designed to be placed on the ware to travel through the E-coat bath (and be removed before the curing ovens). It has a small LiPo battery that must be charged up before it is used.

Check Battery Condition/Wake Logger Up

Hold the unit horizontal with the Blue cap on the left and display screen facing upwards. Rotate the unit towards you 90 degrees and then back to horizontal. The unit should now be awake.

Charge Battery

If the unit does not wake up or you shows the Low Battery display, remove the blue cap and charge the battery with the AC wall charger & micro USB cable. Allow 90 minutes to fully charge. You should see the Battery Ok display now.

Getting ready to Run

If there is data from a previous run, this data will be shown twice. The first tilt is upward 90° with blue cap facing up following arrow displayed, then 180° with blue cap facing down and so forth for a total of five tilts. Connect USB cable or press MCLR button to ‘Un Arm’ the unit.

A good location for the unit is on the front bumper support (so the blue cap is pointing in the direction of travel) for a car body on a convoy conveyor & Ro-Dip conveyor systems. For a Hoist system the unit can be placed just about anywhere and in orientation.

Making the Data Run

The unit will not turn off unless it runs Low Batt or the USB cable is connected. Place on a flat portion of the ware, away from a hole.

After the Run

Remove the logger before the cure ovens and hold steady until you are ready to review data. Good idea is to place the magnet on a steel surface and then review the data with holding it in your hand. If you hold in in your hand you may inadvertently Arm the unit and then the run data will be erased since the unit thinks you want to make another data run.

Low Battery

Full Battery

Ready To Arm

Armed

Logging

Viewing the Data

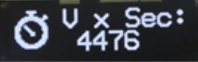

Wake the unit to show the data in the following sequence: Temp, DC V, AC V, # Seconds recorded; and # of Volts x Seconds.

After the Run

Clean the unit with IPA only. Make sure to clean the magnet and the brass tip before the next run.

Factory Default Set-up Parameters

- Termperature Units: C

- InterZone Timeout: 20 Seconds

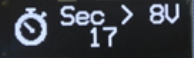

- Trigger: 8 V DC

OLED Screen Icons & Display Examples

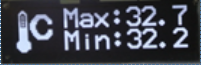

Temperature

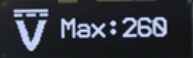

DC Volts

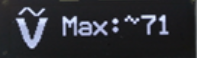

AC Volts (i.e. AC Ripple)

# Seconds above 8 Volts

# of Volts x Seconds

How to Perform 9V Battery Test

Arm the unit. Take the 9V battery and battery cable leads, connect the side of the leads to the top of the battery. Please note touching both cable leads will short 9V battery. Observe the polarity. Next attach the black lead to the magnet. Then attach the red lead to the brass sensor tip for approximately 10 seconds. The logging icon will appear. Disconnect leads and display icons will scroll through.

*Anodic Version

Performing 9V battery test with the anodic model is similiar to cathodic with the exception that cable leads are reversed. Black lead will attach to brass sensor tip with red lead being grounded on magnet. Logging icon will appear and data will commence logging. Disconnecting leads will display results. Please note touching both cable leads together will short the 9V battery.

BULLETIN 994423