E-Coat Current Draw

Product Support and Customer Service

For Further support visit our Contact Page

General

E-coat paint is deposited in direct proportion to the electric current flowing between the anode and the cathode over a certain period of time. The rate at which paint is deposited is called deposition efficiency. In order to calculate the current draw, the following information is required:

- Deposition Efficiency = (Amp-Min)/(µ-m2) [(Amp-Min)/(Mil-ft2)] (from paint supplier)

- Film Thickness Desired = µ (Mils)

- Area per job to be Painted = M2 (ft2)

- Number of Jobs per minute

Example:

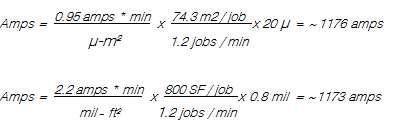

- Deposition efficiency is 0.95 (amp-min)/(µ-m2) [2.2 amp-min/mil-ft2] (black cathodic ED paint)

- Film Thickness is 20 µ [0.8 mil]

- Area per job is 74.3m2 [800 ft2]

- 72 jobs per hour, or 1.2 jobs/minute

Therefore, current required is:

Amps = Deposition Efficiency x Painted Throughput x Film Thickness

The voltage required to operate the E-coat process is dependent upon three factors. The first is the conductivity of the paint (and anolyte). The second is the distance between the anode and the cathode. The third is the conductivity of the ion exchange membrane used in the Anode Cells.

Generally speaking, the higher the conductivity and the shorter the current path, the lower the voltage.

BULLETIN 991003