Diode Applications for Anode Cells

Product Support and Customer Service

For Further support visit our Contact Page General

Diodes are used with Anode Cells to stop ‘reverse current’ conditions. Typically if ‘reverse current’ is occurring in an E-coat system, you will be able to see deposits of e-coat paint on the exterior surface of the membrane on the cell that is operating at a lower voltage than others cells in the same ED tank. Each Anode Cell of the lower voltage zone should have its own separate diode.

How does a diode work?

It serves as an electrical ‘check valve’ in which electrical current can flow in only one direction.

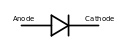

What symbol is used for diodes?

It is an arrowhead pointing into a vertical line. The direction of electric current flow is the same as the direction of the arrowhead.

How is a diode specified?

The diode has a rugged case (i.e. DO-8) and will withstand some limited abuse. Its voltage rating should be twice the maximum expected voltage, and the current rating should be twice the expected maximum current.

Heat Sinks are Required

A diode has a forward voltage drop of between 0.4 V and 0.7 Volts. This voltage drop x the current passing though the diode is the dissipated power the heat sink has to get rid of to keep the diode cool.

What is a reverse polarity diode?

The typical DO-8 type diode has a threaded stud on one side and a flexible pigtail on the other end. The stud is part of the case and it is the cathode of the diode. For a cathode E-coat paint where the Anode Cell is the anode, the diode would be attached to a heat that is connected to the electrode (i.e. anode). If the diode is to be attached to the anode bus bar (which then also serves as the heat sink – make sure the bus bar is large enough and exposed to the ambient for cooling so it can perform this function too), then the case of the diode must be the anode and this type of diode is called a ‘reverse polarity’ type. The photo below show a reverse polarity diode (with the white portion attached to the red Anode cell cable lead) installed on the anode bus bar.

Some E-coat Systems do not need diodes...

Again, lets consider cathodic E-coat paint. If the anode bus bar is common (for all the different voltage zones) and the cathode bus bar is split, then diodes are not necessary. In other E-coat systems, the designer has specified a minimum distance between the last cell of the low voltage zone and the first cell of the high voltage zone. This distance which can be as much as 3 m (~10 feet) is sufficient to reduce the likelihood that the higher voltage electric current can travel far enough to create a reverse current condition(s).

Diodes needs to be checked every year

A diode can fail and so it needs to be checked at least every 12 months. The diode has two be removed from the circuit and tested with a volt meter that has a diode check function. If the forward voltage is not in the normal range then the diode needs to be changed. The diode can fail 'open' so no current can pass through or it can fail 'closed' where there is no reverse current protection anymore.

UFS PN's 285005 and 285006

UFS provides 2 general types of Diodes for installation with Anode Cells. Both are rated at 150 amp, 1000V with regular, or reverse polarity versions and DO-8 case with stud and Pigtail. It is possible to modify the pigtail and use a Quick connect too.

These are manufcatured by EDAL Industries Inc. For more information on the Diodes UFS uses in PN's 285005/285006 download the spec sheets here.

BULLETIN 991118