Precious Metal Oxide (PMx) Anode Inspection

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Required Materials

- Cotton Gloves

Required Tools

- 10x Handheld Microscope

General

UFS provides Precious Metal Oxide anodes when light color or white E-coat paint is used (i.e., the appliance industry) when iron oxides (from the dissolution of iron from stainless steel anodes) can contaminate the ED bath and easily cause an un-wanted color change. BEFORE YOU START: Please keep in mind that PMx anodes are quite susceptible to scratching. Even small scratches and nicks in a PMx surface can cause extremely rapid erosion. Make sure to wear cotton gloves at all times while handling/inspecting the PMx anode. Remove all jewelry, which might come in contact with the Electrode, including rings and watches. The purpose of this Service Reference is to help the E-Coat Tank Operator visually inspect the PMx anodes and look for early signs of trouble. This visual inspection process will provide input into the maintenance of the Cells to help determine spare parts reordering strategies. The following are some typical visual clues that an E-Coat operator can look for when inspecting Precious Metal Electrodes:

- Iridescent Blue - The PMx coating has started to wear away excessively leaving a bluish color behind as oxide starts to develop due to passivation. Note the upmost part is still black (original color) since it was located inside the Collar of the Membrane Shell and little to no current was able to flow off its surface.

- Starting at the horizontal red line is where the electro-chemical reaction is taking place and where the precious metal coating has been worn away. Anode should be checked for the amount of remaining coating before re-installing.

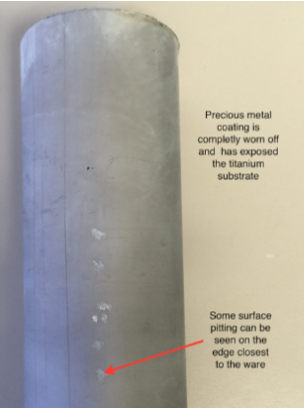

- Surface Pitting – Pitting can start because the precious metal coating is not perfectly uniform across the entire anode surface and some of the titanium substrate can be exposed to the anolyte at a voltage greater than 18 V =, which is the voltage that titanium breaks down and forms titanium di-oxide (whitish powder). If the surface pitting continues long enough then a hole can be seen completely through the wall thickness of the titanium tube.

Suggestion: As a stop gap measure - these pitted areas might be covered with a 2 part epoxy to extend the life until replacements can be received and installed.

- “Powdery” to the touch – If after touching the PMx anode you see a lamp black material or carbon black powder on your gloves, this is called a “spalling” process whereby the PMx coating is losing its adhesion and it’s wearing away.

- “Gray” Surface Appearance - After all the PMx (precious metal coating) is consumed - all that is left is the titanium substrate.

BULLETIN 990161