Membrane Shell Replacement Strategy

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Required Materials

- In service date of all Cells in the ED tank.

Required Tools

- None

-

General

Anode Cells have two components that wear as the Cell is operated and put under load. The first is the metal anode and the other is the Membrane Shell that contains the ion-exchange membrane. The metal anode will erode over time since oxygen is being evolved and it will sacrifice some of the iron in the stainless steel alloy. The ion exchange membrane will age as some of its ion exchange sites fail to operate and thus the remaining sites have to carry more and more load. This is seen by the gradual increase in the DC voltage necessary to deliver the needed current given the E-coat film thickness requirement of the customer.

The mass of the anode can be measured and logged on a regular inspection schedule. Once 60% of the original mass has been lost then it’s time to request replacements and begin a process to change them out over the next 12 months (give or take). See Bulletin 990129 for more information.

The 1-1/2 inch TECTRON Membrane Shells can usually last about 20,000 hours as long as the anode current density has not been more than 55 amps/m^2 (5 amps/SF). For the 2 inch TECTRON Cell the hours are 18,150, 3 inch TECTRON Cell it is 17,750 hours, and for the 5 inch TECTTRON Cell the lifetime is 16,900 hours.

Eventually the Surface Resistance of the ion-exchange membrane will increase to a point where replacement Cells (or new Membrane Shells and used anodes) are justified because of the extra voltage required or the occurrence of too many E-coat film defects related to high voltage. Careful planning in the placement of the new Cells will ensure that you get the fullest life possible from the replacements. The Cells at the entry of the E-coat tank (monorail conveyor), in the front part of each electrical zone (automotive ED tank), or in the middle of the E-coat tank (hoist or indexing conveyor) will suffer the greatest wear and need to be replaced first. The Cells in the other places of the E-coat tank probably have some more life left in them and can be replaced second.

All the anode cells do not operate at the same level and hence do not wear out at the same rate. Hence it is ok to change out the cells over a 12 month time frame. Two of the more common replacement philosophies are the ‘One Third’ at a time strategy and the ‘Half’ at a time strategy.. For the purposes of this document, it will be assumed that all the Anodes will be reused.

One Third

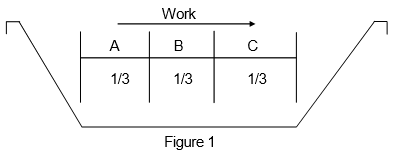

This replacement schedule is applicable for monorail systems only. It will allow the Membrane Shells to be replaced over the course of a year. Divide the E-coat tank into thirds as shown in Figure 1. NOTE: If your ED system has different voltage zones, then your thirds will be spread out.

- First Third - Pull all the Anodes from the Shells in region A and set them aside. Remove all the Shells from region A and discard.

- Pull all the Anodes from the Shells in region B and set them aside. Move the Shells from region B to region A and replace the Anodes into the moved Shells.

- Pull all the Anodes from the Shells in region C and set them aside. Move the Shells from region C to region B and replace the Anodes into the moved Shells. Place all the new Membrane Shells into region C and replace the Anodes into the new Shells.

- Second Third - In about 6 months repeat steps 1 through 3. Keep some of the better used Shells taken from region A and save as emergency spares.

- Final Third - In another 6 months repeat steps 1 through 3.

Half

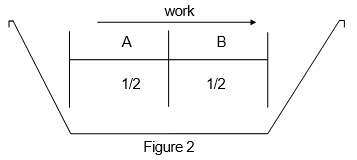

This replacement schedule will work in both hoist and monorail systems. It also allows for Membrane Shells to be replaced within a year's time period. Begin by dividing the E-coat tank in half. See Figure 2 for monorail systems. See Figure 3 for hoist systems.

- Pull all the Anodes from the Shells in region A of the tank and set them aside. Remove all the Shells from this region and discard.

- Pull all the Anodes from region B and set them aside. Move the Shells to Region A and replace the Anodes. Place the new Shells in region B. Replace the Anodes into the new Shells.

- Repeat steps 1 and 2 in six months.

HINT: Some of the Membrane Shells that are still working well when removed can be kept as emergency spares. HINT: Annual cleaning is essential to reduce or prevent paint contamination and keep the Membrane Shells working longer at an optimal level.

BULLETIN 990157