High ED Paint Bath pH (Cathodic ED paint)

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Required Materials

- Titration Equipment

- Titration Solutions

Required Tools

- None

-

General

It is not unusual for the pH of the E-coat bath with new Anode Cells to operate on the high side. This is not all bad as neutralizer (i.e. acid) can be added to adjust the E-coat bath. The E-coat system loses acid in one of four ways: 1) UF permeate purge; 2) dragout of rinse water from the post rinses; 3) some acid in the E-coat film; 4) the Anode Cell system. Generally, the first three losses are fixed for each production rate and product mix. Acid is always being added whenever replenishment paint is added to the bath. In order to achieve a better balance (i.e. add less acid to maintain a more stable ED bath pH), the following actions are possible (listed in order):

- If you are using precious metal anodes, then it may be possible to return some of the anolyte back directly into the E-coat bath, in order to reduce the net removal rate of neutralizer from the E-coat bath. On the other hand, if you are using 316L anodes, then this is not possible since the dissolution by-products of the 316L anodes would be going into the bath, which can increase the dissolved iron ppm and may cause orange peel type paint defects. Talk to your E-coat paint supplier about returning a small amount of anolyte (only -if you use a precious metal anode). UFS would like to participate in this decision making process, so please involve us.

- Use several Neutral Membrane Cells (with precious metal anodes). These Cells overflow directly back into the paint bath without the use of a recirculation loop. (Note Neutral membranes do not function properly with all ED paints. In some cases a bench top test will have to be conducted to confirm suitability with your ED paint type by UFS before they could be used).

- If PTAN membrane is being used along with precious metal anodes, then it is possible to use PTAR membrane on some of the Anode Cells. PTAR membrane has a higher permeation rate with respect to water and so will lose more anolyte into the bath than would PTAN membrane. Please discuss this with your E-coat paint supplier and UFS.

- Increase conductivity of anolyte. (This has a rather small impact, much like a fine adjustment on a DC rectifier voltage adjuster.)

- Use bare anodes (last resort). While this is the lowest cost method, it also leads to creation of dirt bits in paint bath because the ED paint bath comes into contact with the surface of the bare anode, which can have a pH (near its surface) of 3, or less.

The purpose of the remainder of this bulletin is to investigate the actual rate of diffusion of neutralizer (i.e. acid) from the ME Cells (i.e. anolyte system) back into the E-coat bath.

- Take an in-depth look at input and output to the E-coat bath. The time period for the evaluation should be at least one week and maybe as long as one month.

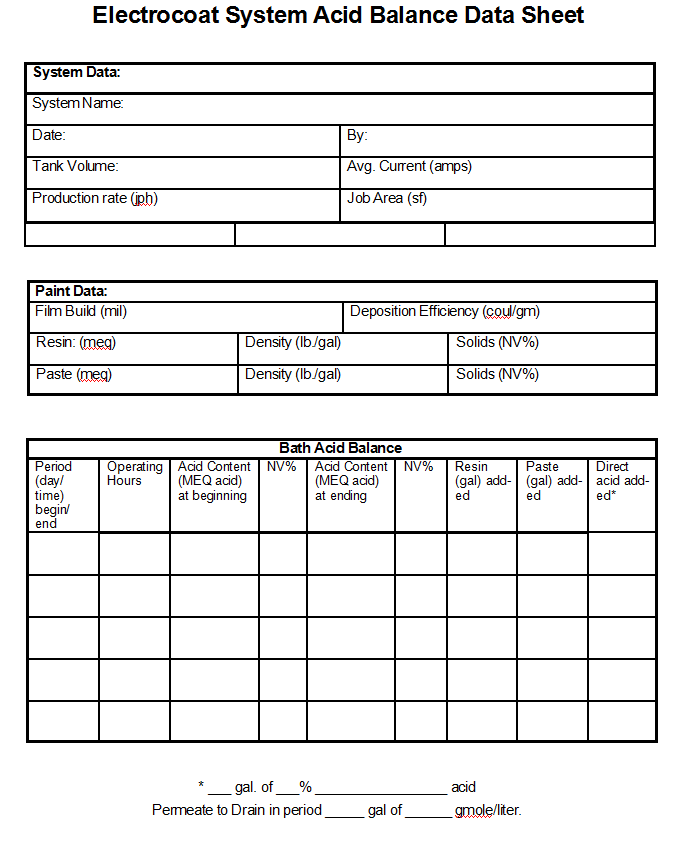

- Use the attached form to take readings for five consecutive off shifts. It is necessary to measure the acid concentration and report the figures in MEQ acid/liter.