Retrofitting Box Cells with Tectron Anode Cells

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Required Materials

- 1-1/2” Metal 2-Piece Clamps (UFSc P/N 310011)

- Heavy Body Cement

- Teflon Tape

Required Tools

- Welder

- Pliers

- Screwdriver

- 3 lb Hammer

- Crescent Wrench

General

The 8’ Cell Support Frame and it’s accompanying electrolyte supply (P/N 370103) and Return Branches (380106) allow for quick installation of TECTRON ME Cells to replace box or crescent-shaped cells. The Frame size is determined by the width of the old cell and the gap between them. For example, if your old cell is 1016 mm (40”) wide and there is a 508 mm (20”) gap on either side of each old cell, then the length of the Frame will be 1524 (60”).

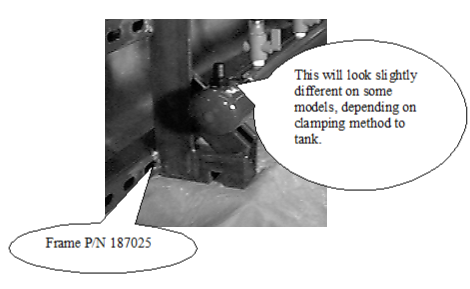

After the “old” box cell is removed, the Cell Support Frame is placed on the rim of the tank and secured. Next, the Supply Branch is attached to the Frame and connected to the existing supply manifold. Finally the Return Branch should point towards the TECTRON Cell anywhere from 30 to 60 degrees from the vertical direction. This is done to promote the gravity return flow of the electrolyte solution of the ME cell. =Frame PN 187025

Step 1

After the box cells are removed, insert the Cell Frame (P/N 187025). The Frame is made such that it can be adjusted to fit securely to tank pipes with an approximate width of 4” - 5”. The placement of the first frame (on each side) is important because all the others will have to be attached (if additional frames are ordered). After the Frame has been set in place, use a tape measure to insure that there is the same spacing on either side of it.

Make sure that the adjustable clamps at the bottom of the angle iron are over the rim of the ED tank. Use a welder to secure each of the angle brackets to the rim of the tank. Do not damage the ED tank lining. If necessary, drill holes through the angle brackets and the rim of the ED tank and use bolts and buts to secure.

Mini Supply Manifold P/N 370103

Step 3

Set the Supply Branch (P/N 370103) on the diagonal strut channels with the hose barb pointing up. The branch needs to be as high as possible, so the return tubing from the ME Cell can pass underneath the Supply Branch. Use two clamps to secure the Supply Branch to the Frame.

Step 4

Use the loose 1/2” MPT x 5/8” hose barb adapters and 1/2” couplings (slipped over the VP16 pipe) in the existing supply manifold. Slip over a worm clamp, a length of braided tubing, and push the tubing over the 5/8” hose barb adapter. Secure by tightening the clamp. Repeat the process for the supply branch. (Usually the hose barb is already installed in the branch.)

Step 5

Now you can install the nine (9) Flow Indicator Valves (P/N 225042). If there will be more than four TECTRON ME Cells used to replace the old cell, remove one of the plugs from the supply branch and install another Flow Indicator Valve.

Mini Return Manifold P/N 380045

Step 6

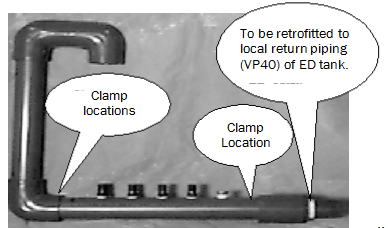

The return branch is provided mostly in loose form because it has to be retrofitted to the local piping of the ED tank. The connection point is a NPT nipple. Generally there is a threaded elbow (at the rim of the ED tank) into which the return branch can be connected.

Step 7

There are match marks on the loose parts. Thread the nipple/coupler into the existing elbow.

Step 8

Use PVC primer and glue to attach the portion with the pre-assembled hose barbs. Take note to position the hose barbs leaning towards where the TECTRON ME Cell will be located. (This will help guard against kinking.)

Step 9

Glue the elbow on next, followed by the vertical section of pipe and then the goose neck vent.

Step 10

Install a shim near the elbow to support the return branch and insure that there is a 1-2% slope down.

BULLETIN 993164