T5 Quick Start

Contents[Show]

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Installation Sequence

- Unpack the T5 ME Cell carefully! First remove any exposed nails or screws on crate that could damage the Cell.

- All of the brackets have been installed at the factory for proper installation. The brackets may have to be tightened and or loosened.

- Install electrode into membrane shell (do not allow electrode to fall into membrane shell because damage will occur). Once the electrode has been installed tighten the riser clamps to avoid any slippage.

- Place hoist (with bolt that goes through the neck of the T5 with holes provided) to lift T5 into the paint tank. Note: T5 will have to be guided into place to avoid any obstructions that may cause damage to the T5 membrane shell.

- If paint tank is full, slowly fill up the cell with Di or RO water before lowering into place . If paint tank is empty, slowly lower the T5 into place (the T5 will have to be full of anolyte before paint is put back into paint tank).

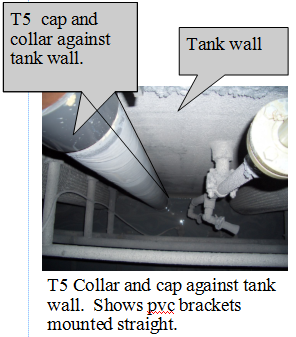

- The pvc brackets will have to be adjusted to assure proper placement of T5.

- To adjust pvc brackets place T5 against the tank wall and then tightened the pvc brackets. Note: Brackets must be straight and the T5 must be against tank wall.

- Hook up electrical—connect cable lead to electrode and busbar.

- Hook up return and supply tubing to corresponding tank piping.

- T5 is ready for operation.

BULLETIN 993421