Features:

Logger has 5 LEDs, each one represents 20% of design life. If all 5 are lit, there is between 80% and 100% of useful life remaining; if 4 are lit, remaining life is 60% to 80%, and so on. When only one LED is lit, it is time to plan replacement of the anode cell.

When the last red LED flashes, then less than 10% of life is left.

Useful life is pre-programmed into unit, based on the surface area of the ion-exchange membrane.

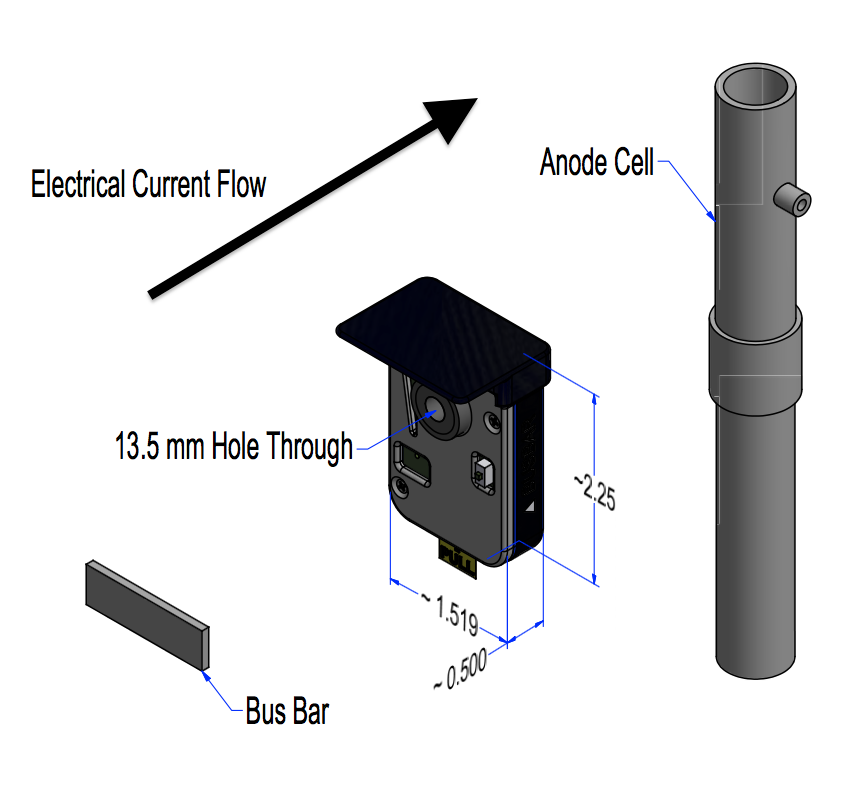

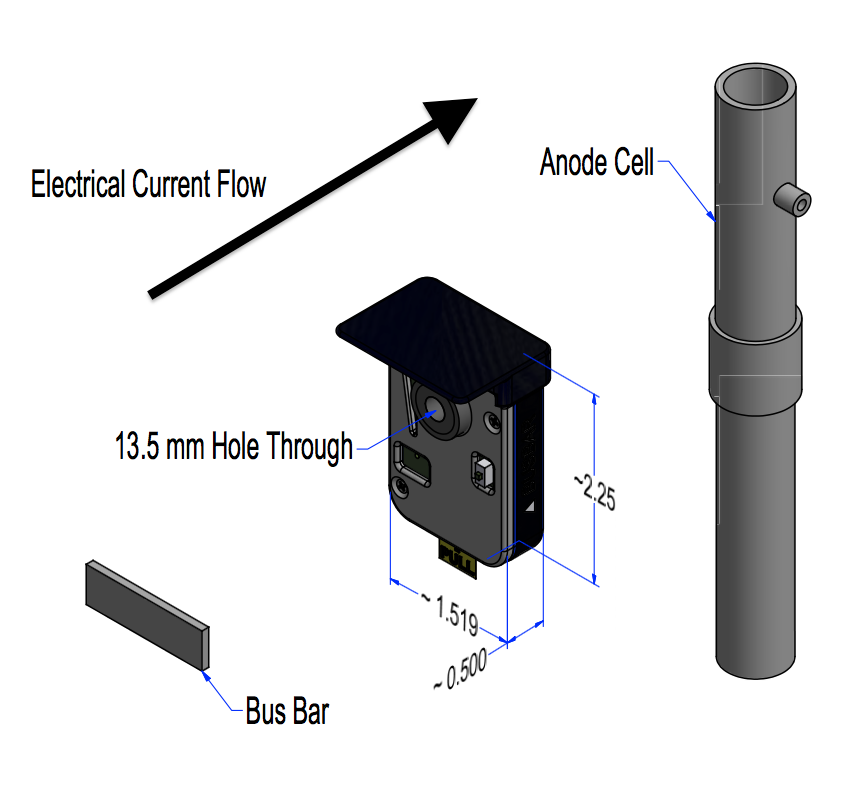

Small size fits easily on the electric cable lead, and uses a Hall Effect sensor to measure current.

Fits all wire sizes up to a #2 cable, 13 mm (0.51 in.) O.D. max.

Includes a self-contained standard CR2032 battery and microprocessor.

Has capacity to measure up to 100 amps.

Battery voltage is monitored by separate LEDs.

Not reusable.

Properties:

The Logger is compatible with Box Cells, C Cells and Tubular Anode Cells.

LEDs illuminate with the push of a button.

Even after all the LEDs have been exhausted, the E-coat operator can test for electric current passing through the anode cell by using a hand-held ammeter.

UFS recommends installing a TruAmp100 Logger on each brand new anode cell/membrane shell/ membrane change.

The TruAmp100 Logger is a suitable option when budget constraints do not allow the purchase of a New Generation Anode Monitor - (PLC Based System that provides real time current data plus tallies amp hours).

Benefits:

Forecast spare parts purchasing with enough lead time to avoid un- scheduled shutdown or emergency ordering.

No more guessing when the ion- exchange membrane needs to be changed.

Not every cell needs one.

Spacing out units on different cells on just one side of the tank will give accurate measurements and will allow you to reduce initial expense.

Cost effective and practical.