Loose Wrap on Membrane Shell

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

General

The outer wrap performs an important function, which is to provide support for the ion exchange membrane when the ED paint bath level is lowered. Under these conditions, a significant hydrostatic force caused by the head of electrolyte inside the ME Cell occurs. The wrap also supports the membrane of an Low Profile Cell, which are pressurized.

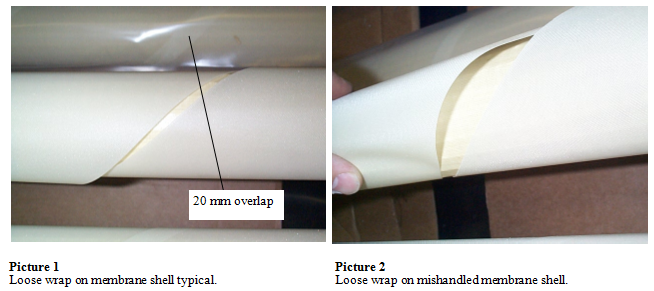

The wrap will often become loose because of handling, during storage, or when membrane becomes dry. To avoid loosening of the wrap, handle membrane shells by the cap and collar not the wrapped area. The membrane tends to shrink with the lack of humidity, causing the wrap to loosen (see pictures below). To avoid these conditions, keep shells in the protective bags during storage or handling.

In order to correct this condition, slowly work the wrap with your hands so that there is a 20 mm overlap throughout the shell as shown in picture 1. When the membrane becomes hydrated the membrane will expand causing the wrap to become tightened. Loose wrap does not happen frequently, but if it does, only a few minutes are necessary to fix this condition.

Wrap dimensions are set at the time of manufacturing to provide proper support when installed in ED paint tank. Wrap that appears loose due to handling or membrane dehydration, when corrected as outlined above, will function properly when installed.

BULLETIN 99